- New technique from Peking and Cardiff Universities promises CO2-free hydrogen production.

- Utilizes bioethanol and water at 270°C, significantly lower than conventional methods’ 400°C-600°C requirements.

- Employs a bimetallic catalyst to eliminate carbon emissions entirely.

- Produces acetic acid as a valuable byproduct, benefiting textile, pharmaceutical, and food industries.

- Currently, 96% of hydrogen production relies on fossil fuels, emitting 12 tonnes of CO2 per tonne of hydrogen.

- Offers a sustainable alternative to fossil fuel feedstocks with reduced environmental impact.

- Signals potential shift towards a cleaner, circular economy for industry giants.

- Represents a significant step towards a sustainable future with efficient hydrogen production.

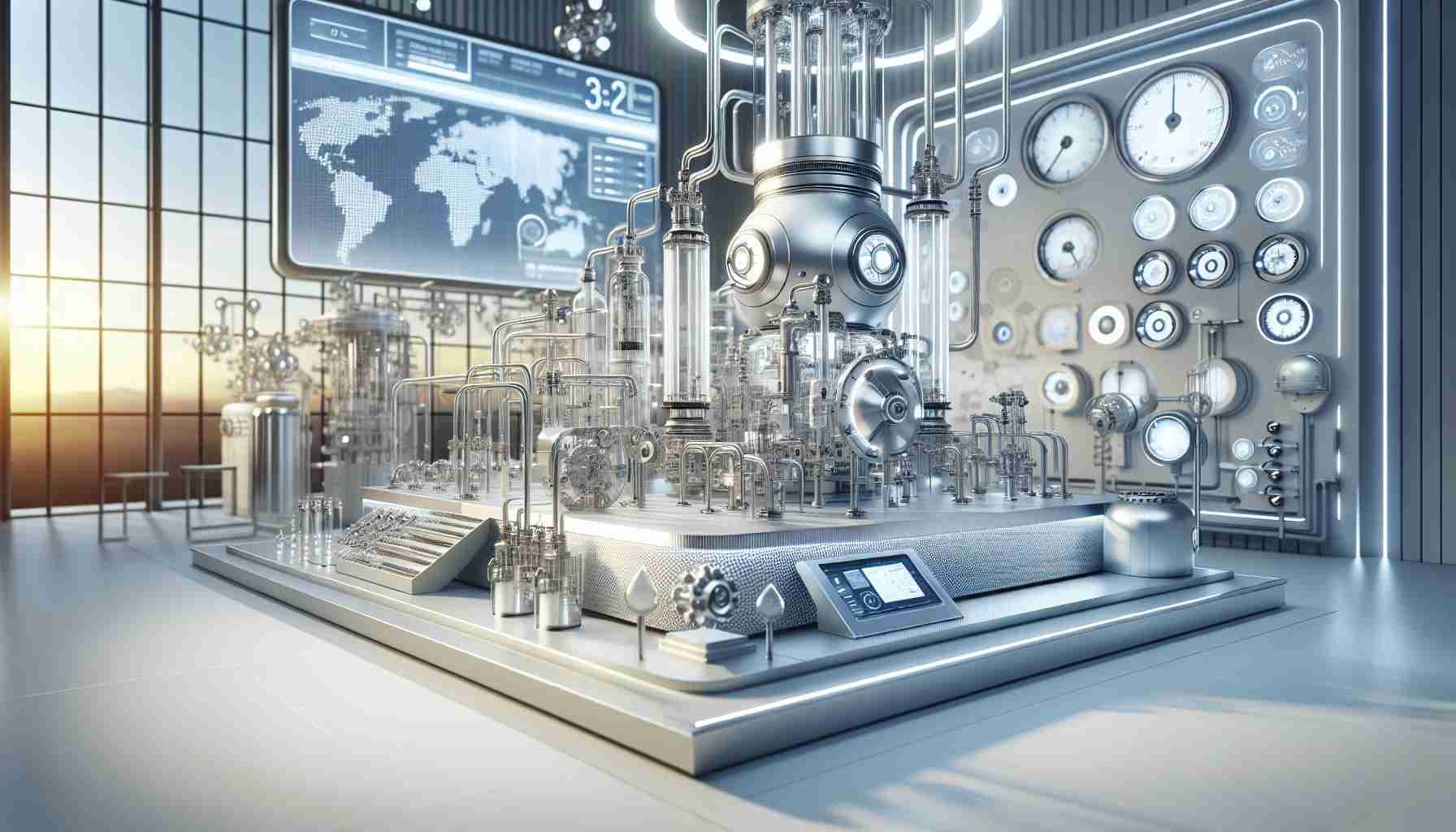

A groundbreaking technique emerges from the bustling labs of Peking University and Cardiff University, promising to transform the hydrogen production landscape. Scientists have crafted a method that not only strips the process of its grievous carbon dioxide emissions but also spins acetic acid—a sought-after industrial chemical—into the mix.

Imagine bioethanol, harvested from the detritus of agricultural endeavors, engaging in a transformative dance with water at a modest 270°C. This is a stark contrast to the soaring 400°C to 600°C typically demanded by conventional methods like steam methane reforming, notorious for their insatiable energy demands and significant carbon footprints. Through the elegant utilization of a bimetallic catalyst, this new approach sidesteps CO2 emissions entirely.

As a byproduct, acetic acid, integral to the textile, pharmaceutical, and food preservation industries, emerges without the usual environmental toll. By weaving the creation of hydrogen and acetic acid seamlessly together, this pioneering method offers a tantalizing glimpse of a carbon-light future for industry giants reliant on acetate fibers and pharmaceutical components.

Currently, the world grapples with hydrogen production that’s 96% dependent on fossil fuels, belching up to 12 tonnes of CO2 per tonne of hydrogen produced. Yet this innovation presents a beacon of hope, spotlighting a potential shift from traditional fossil feedstocks to sustainable biomass alternatives.

This breakthrough is more than an academic triumph; it is a clarion call for change. By enabling a cleaner, more efficient hydrogen production cycle, the path towards a sustainable, circular economy seems more accessible than ever before, inviting industries worldwide to imagine—and embrace—a brighter, greener future.

Revolutionary Sustainable Hydrogen Production: The Future of Clean Energy Unveiled

How This Breakthrough in Hydrogen Production Works

The revolutionary hydrogen production method developed by Peking University and Cardiff University is a game-changer in the clean energy sector. Employing bioethanol derived from agricultural waste, this method dramatically reduces the carbon footprint by operating at a significantly lower temperature of 270°C, compared to the 400°C-600°C required by conventional techniques.

How-To Steps & Life Hacks for Implementing This Technology

1. Source Bioethanol from Agricultural Waste: Utilize waste from agricultural activities to ensure sustainability and cost-effectiveness.

2. Use the Bimetallic Catalyst: Implement the use of a bimetallic catalyst to facilitate the chemical reaction between bioethanol and water efficiently.

3. Optimize Reaction Conditions: Maintain the reaction temperature at around 270°C to maximize hydrogen production while minimizing energy consumption.

4. Capture Byproduct Acetic Acid: Utilize the generated acetic acid in various industrial applications, adding value to the process.

Real-World Use Cases

Industries reliant on hydrogen and acetic acid such as textiles, pharmaceuticals, and food preservation can greatly benefit from this technology:

– Textile Industry: Use acetic acid in the production of acetate fibers.

– Pharmaceutical Industry: Acetic acid is crucial for formulating various pharmaceutical products.

– Food Industry: Acetic acid is employed as a preservative and flavor additive.

Market Forecasts & Industry Trends

The global hydrogen market is expected to reach $230 billion by 2030, driven by the demand for cleaner energy solutions and the reduction of industrial carbon emissions. This breakthrough aligns perfectly with industry trends emphasizing sustainability and circular economy practices.

Controversies & Limitations

While promising, the scalability and economic viability of this method need thorough evaluation. Large-scale adoption requires substantial initial investment in infrastructure and technology adaptation.

Security & Sustainability

This method enhances energy security by reducing reliance on fossil fuels and promoting the utilization of renewable biomass resources. From a sustainability standpoint, it significantly lowers carbon emissions, contributing to global greenhouse gas reduction efforts.

Pros & Cons Overview

Pros:

– Reduces CO2 emissions

– Operates at lower temperatures, reducing energy demand

– Produces valuable acetic acid byproduct

– Utilizes renewable biomass resources

Cons:

– Initial investment costs and infrastructure adaptation

– Scalability challenges for widespread industry adoption

Recommendations and Quick Tips

– For Industries: Begin evaluating the potential integration of this technology to future-proof your operations against environmental regulations and market shifts.

– For Policymakers: Encourage and incentivize research and development in sustainable energy technologies.

– For Investors: Consider directing investments towards companies focusing on sustainable hydrogen production innovations.

Leverage this groundbreaking technology to stay ahead in the transition to cleaner energy. Stay informed by frequently visiting credible energy journals and institutions like the Department of Energy to keep updated on industry advancements.

This technique underscores a critical shift towards sustainable energy solutions, inviting us all to envision a cleaner, greener future.