- Honda launches a certified collision program specifically for electric vehicles, led by John Peixoto.

- Repair shops must attain Honda and Acura certifications to qualify for the EV-specific badge.

- Shops need upgraded tools, including a pneumatic riveting system and special equipment for EV cooling systems.

- Personal safety equipment, like class zero gloves, is essential for high-voltage work.

- Honda and I-CAR offer a comprehensive training program combining online study and hands-on experience.

- Repair shops can choose to perform high-voltage operations or send them to dealerships.

- Maintaining optimal conditions in paint booths is crucial to preserve EV battery integrity.

- Honda’s program emphasizes precision, safety, and innovation, leading the EV repair industry.

A new era of automotive repair has arrived as American Honda sets into motion a groundbreaking certified collision program tailored specifically for electric vehicles. This initiative, spearheaded under the watchful eye of Honda’s Wholesale Marketing Assistant Manager, John Peixoto, represents a strategic enhancement of their longstanding commitment to innovative repair standards.

Imagine the smooth curves of a gleaming Honda Prologue or the sleek elegance of an Acura ZDX, future-forward vehicles now backed by an evolving certification that promises to adapt in tandem with advancing EV technology. By 2026, Honda aims to unveil the pioneering Honda 0 Series platform—two vehicles poised to redefine the automotive landscape—and they will roll onto the scene, supported by this cutting-edge collision repair framework.

The pathway to certification weaves through comprehensive prerequisites: repair shops must first attain Honda and Acura certifications before they can qualify for the EV-specific badge. Each detail—like the sturdy grip of a vehicle lift or the calibrated weight of a frame bench—has been meticulously upgraded to accommodate these robust electric machines.

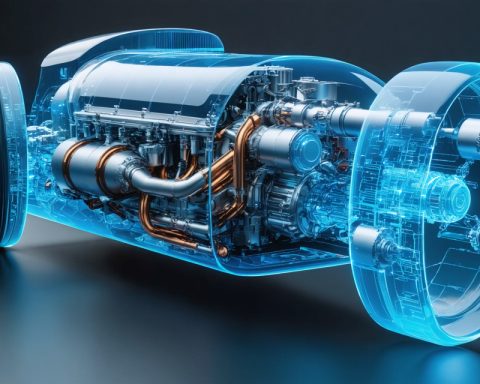

Scrutinizing the intricate details of repair, Honda suggests that shops prepare for the electric age with specialized tools, like a pneumatic riveting system to secure structural elements or bespoke instruments to navigate the labyrinthine EV cooling systems.

Safety remains paramount. Personal protection equipment such as class zero gloves or a lockout/tagout kit ensures that no detail is overlooked in the high-stakes environment of high-voltage repair.

The educational framework supporting this program is as extensive as it is essential. American Honda and I-CAR have crafted a robust curriculum, blending 10 hours of intensive online study with a rigorous five-day immersive training session at Chicago’s esteemed Technical Center. Here, hands-on experience drives home the critical importance of mastering safety procedures around intricate high-voltage systems.

Shops face a critical decision in choosing to send vehicles back to Honda and Acura dealerships for high-voltage operations, though they do have the autonomy to handle these delicate tasks internally, guided by a foundational tool list and the expertise required by Honda’s high standards.

In this meticulously engineered ecosystem of repair, even the paint booth has new, critical guidelines. Shops are reminded—through Honda’s communications—that maintaining precise conditions in curing processes is crucial. The delicate dance of temperature and timing ensures that structural adhesives set without compromising high-voltage batteries.

The bold rollout of Honda’s certified EV collision program signals a thrilling chapter for collision repair—where precision, safety, and cutting-edge innovation intersect. As the world hums steadily toward an electric future, Honda leads the charge, offering repair shops a golden opportunity to rise to the forefront of this electrifying transformation.

Unlocking the Future of Automotive Repair: Honda’s Revolutionary EV Collision Program

Insights into Honda’s New Collision Repair Certification for Electric Vehicles

In a significant leap toward the future of automotive repair, American Honda has launched a pioneering certified collision program tailored specifically for electric vehicles (EVs). Under the strategic guidance of John Peixoto, Honda’s Wholesale Marketing Assistant Manager, this initiative is set to enhance repair standards, focusing on EV-specific requirements and safety protocols. As the demand for electric vehicles increases, Honda’s program is perfectly timed to address emerging market needs.

Real-World Use Cases & Market Forecasts

As the Automotive Industry leans more towards electrification, Honda’s initiative arrives when certified repair shops must adapt quickly. By 2026, when Honda unveils the Honda 0 Series platform, vehicles like the Honda Prologue and Acura ZDX will benefit from this advanced collision repair framework. This reflects a broader market trend where certified repair programs become essential to maintaining vehicle standards and safety in advanced EVs.

How-To Steps & Life Hacks for Certification

1. Obtain Initial Certifications: Repair shops are required to first acquire existing Honda and Acura certifications.

2. Secure Tools and Equipment: Invest in specialized tools, such as pneumatic riveting systems and specific EV cooling system instruments.

3. Enhance Safety Protocols: Equip your workshop with essential Personal Protection Equipment (PPE), including class zero gloves and lockout/tagout kits.

4. Enroll in Training Programs: Participate in the comprehensive 10-hour online study and attend the five-day hands-on training session at Chicago’s Technical Center.

5. Maintain Paint Booth Standards: Ensure optimal conditions for curing processes, crucial to maintaining vehicle integrity and safety.

Reviews & Comparisons

Compared to other industry players, Honda’s EV certified collision program distinguishes itself through its robust training regimen and emphasis on EV-specific tools and safety equipment. While other manufacturers might have similar certifications, Honda’s partnership with I-CAR and dedication to high-voltage safety protocols sets a higher benchmark.

Security & Sustainability Considerations

The program is deeply embedded with sustainability principles by extending vehicle lifespans and ensuring safe repair processes. The emphasis on safety and specialized tools not only protects technicians but also preserves the integrity of high-voltage systems, thus ensuring sustainable repair practices.

Controversies & Limitations

While the program offers numerous benefits, shops may face challenges in investing in the required equipment and training, both financially and logistically. Some smaller repair operations might find it difficult to meet the high entry bar set by the program’s requirements initially.

Actionable Recommendations

1. Investment in Training and Equipment: Ensure your shop is prepared to meet the growing demand for EV repair services.

2. Leverage Honda’s Support: Utilize available resources from Honda for training and tool procurement.

3. Stay Updated on Industry Trends: As EV technology progresses, continually update your knowledge and facility’s equipment to stay compliant.

4. Promote Your Certification: Use this certification to build credibility and attract more customers seeking specialized EV repair.

In conclusion, Honda’s certified collision program for EVs offers a promising direction towards more precise and safer automotive repairs. As the industry propels into an electric future, shops certified under this program can position themselves as leaders in this electrifying transformation. Look into Honda’s official Honda website for more details on their innovative offerings and further resources.