- Novelis Inc. is pioneering a bold initiative in Latchford, substituting hydrogen for natural gas to power an aluminum recycling furnace.

- The trial, part of the UK’s decarbonization strategy, showed potential to reduce emissions by up to 90%.

- Collaboration with Progressive Energy ensured the trial prioritized safety and efficiency.

- This effort creates eco-friendly aluminum products and is a significant step towards a zero-carbon future.

- Novelis plans to double its recycling capacity while significantly cutting CO2 emissions, aligning with the 3×30 vision for enhanced recycling content and circularity.

- The initiative positions Latchford as a prototype for sustainability, leveraging renewable energy to meet ecological demands.

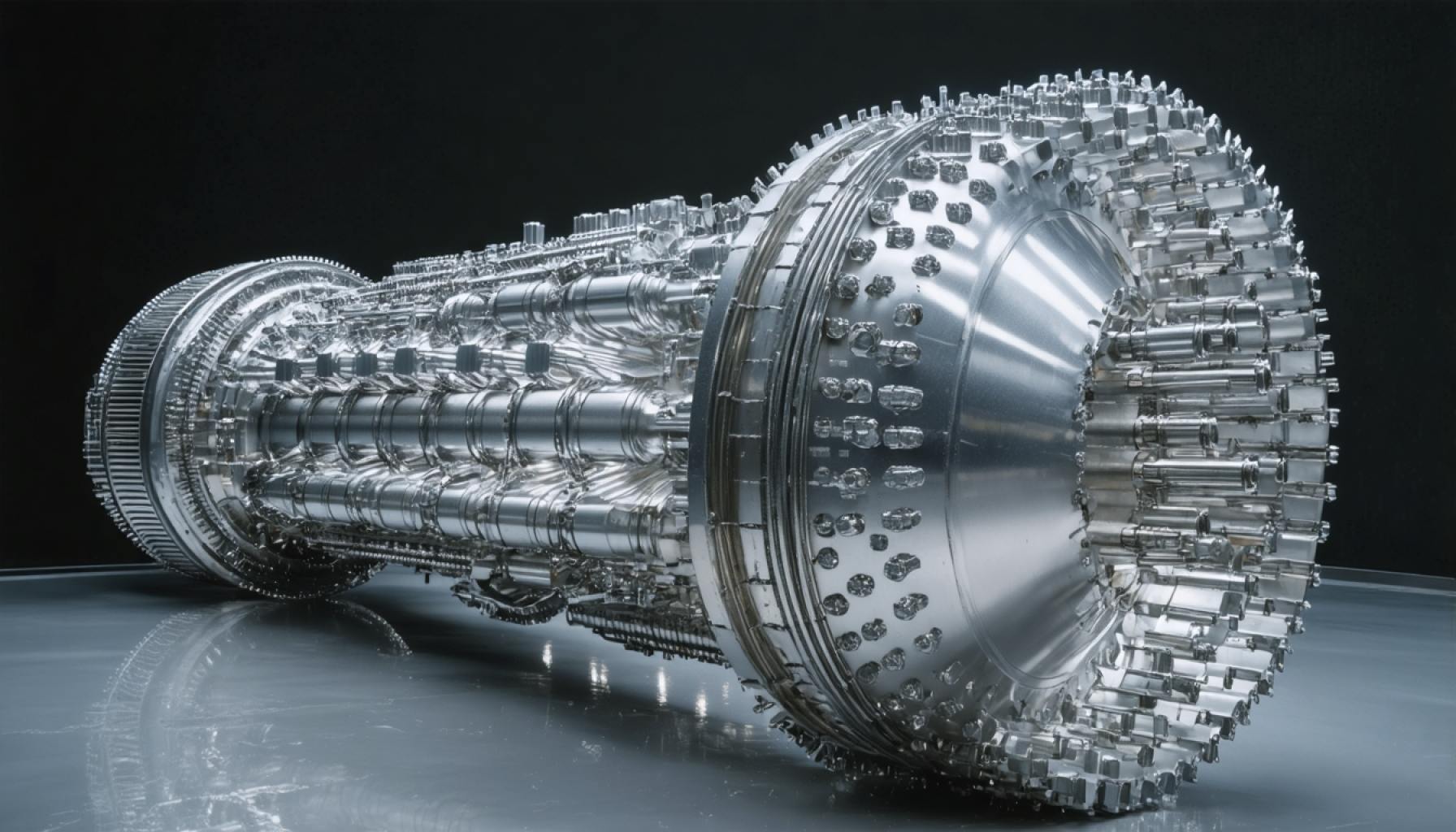

A bold new chapter unfolds in the heart of Latchford as Novelis Inc. sparks anticipation with a trial run that could redefine the aluminum industry. In a pioneering effort to embrace sustainable energy, the company recently tested hydrogen fuel in place of natural gas to power a recycling furnace at its UK plant. With emissions slashed by up to 90%, the trial sets the stage for what might be the metal industry’s leap towards a zero-carbon future.

This initiative, a part of the UK government’s decarbonization efforts, converts hydrogen into a torch of possibility. In collaboration with Progressive Energy, Novelis meticulously ensured each step prioritized safety and efficiency. By gradually blending hydrogen with natural gas, they tested the waters for compatibility concerns, while re-melting large volumes of scrap aluminum. The result? Eco-friendly sheet ingots that whisper promises of a greener tomorrow.

Downstream, further processing in European plants aims to sculpt a full-circle hydrogen-based production process. As these trials conclude, Novelis prepares to report on their findings as a beacon of sustainable innovation in the UK government’s Industrial Fuel Switching program.

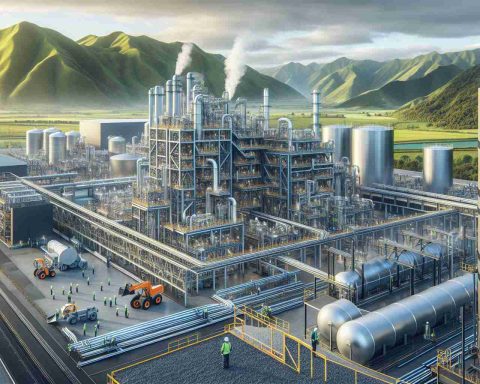

Yet, Latchford’s tale isn’t merely a technical triumph. It’s a hopeful vision set amidst overcast skies. Novelis’s investment promises to double recycling capacity while slashing CO2 emissions, inching closer to the 3×30 vision—a roadmap for recycling content, reduced emissions, and industry-leading circularity.

Brimming with ambition, Novelis transforms Latchford into a prototype for sustainability. Amidst rising ecological demands, their commitment to renewable energy and technological breakthroughs lights the path for an industry ready to evolve. The message is clear: with hydrogen at its heart, aluminum’s future shines bright and green.

Hydrogen Power Revolution: Novelis Inc. Paves the Way for a Sustainable Aluminum Industry

How-To Steps & Life Hacks: Implementing Hydrogen Fuel in Industrial Processes

1. Identify Potential Applications: Begin by assessing areas within your industrial operations where hydrogen could substitute traditional fuels. For instance, Novelis targeted their aluminum recycling furnace.

2. Conduct Feasibility Studies: Evaluate the technical and economic viability of switching fuels. Consider factors such as existing infrastructure compatibility, hydrogen supply logistics, and regulatory support.

3. Partner with Experts: Collaborating with industry leaders like Progressive Energy ensured Novelis tackled safety and efficiency challenges head-on.

4. Pilot Testing: Implement controlled trials, gradually increasing the proportion of hydrogen used, as Novelis did by blending it with natural gas.

5. Monitor & Evaluate: Gather data throughout the trial to assess emissions reductions and operational impacts. Novelis reported up to 90% reduction in emissions.

6. Scale-Up: Once successful, plan for wider scale implementation to maximize environmental benefits.

Real-World Use Cases: Expanding Hydrogen Applications

– Steel Manufacturing: Similar to aluminum, steel can benefit from hydrogen in reducing carbon emissions during production.

– Glass Production: Hydrogen can serve as a cleaner energy source for the high-temperature processes typical in glass factories.

– Transportation: Freight and public transport sectors are increasingly exploring hydrogen as a clean energy alternative.

Market Forecasts & Industry Trends

The global push for sustainability predicts a boom in hydrogen fuel technology. According to a report by Allied Market Research, the hydrogen generation market could reach $201.8 billion by 2025, driven by policies focusing on emissions reduction and advanced technology adoption.

Reviews & Comparisons

– Hydrogen vs. Natural Gas: While hydrogen offers lower emissions, it presents storage and infrastructure costs that are typically higher than natural gas.

– Renewable Hydrogen vs. Grey Hydrogen: Renewable hydrogen produced via electrolysis using renewable energy sources is more desirable, though currently more costly than grey hydrogen derived from fossil fuels.

Features, Specs & Pricing

– Hydrogen Production: Costs vary dramatically by production method, with electrolysis generally more expensive than Steam Methane Reforming but increasingly cost-competitive as technology advances.

– Storage & Distribution: Requires robust infrastructure development akin to existing natural gas pipelines, yet innovations in storage technology are closing the gap.

Security & Sustainability

Hydrogen use marks significant sustainability advances, slashing emissions drastically. However, security of supply and price fluctuation remain pressing issues, necessitating multi-nation collaborations and investments in infrastructure.

Insights & Predictions

– Industry Shift: Expect increased industry-wide adoption, especially in sectors like chemicals, where hydrogen plays dual roles as a feedstock and fuel.

– Policy Support: With strong governmental backing, similar initiatives to Novelis’s will likely proliferate, fostering a global hydrogen economy growth.

Pros & Cons Overview

Pros:

– Significant reduction in CO2 emissions.

– Potential for energy independence with domestic hydrogen production.

– Enhances overall plant efficiency and modernization.

Cons:

– High initial investment and infrastructure adaptation costs.

– Hydrogen storage and safety pose technical challenges.

– Market development and scaling still in early stages requiring government incentives.

Actionable Recommendations

– Begin Small: Start with pilot projects and scales adaptable to your specific industrial requirements.

– Follow Regulatory Developments: Engage actively with policy discussions to capitalize on incentives and shape supportive frameworks.

– Join Collaborative Networks: Connect with companies like Novelis and industry consortia to share knowledge and drive innovation.

Overall, the promising results from Novelis’s hydrogen trial offer a roadmap for companies keen on reducing their carbon footprint and embracing more sustainable operations.