Revolutionizing the Maritime Hydrogen Landscape

Lloyd’s Register (LR) has granted an Approval in Principle (AiP) to HD Korea Shipbuilding & Offshore Engineering Co., Ltd. (HD KSOE) for an innovative vacuum-insulated liquid hydrogen (LH2) tank system. This recognition comes after successful testing of a large-scale vacuum chamber, marking a significant milestone in maritime hydrogen technology.

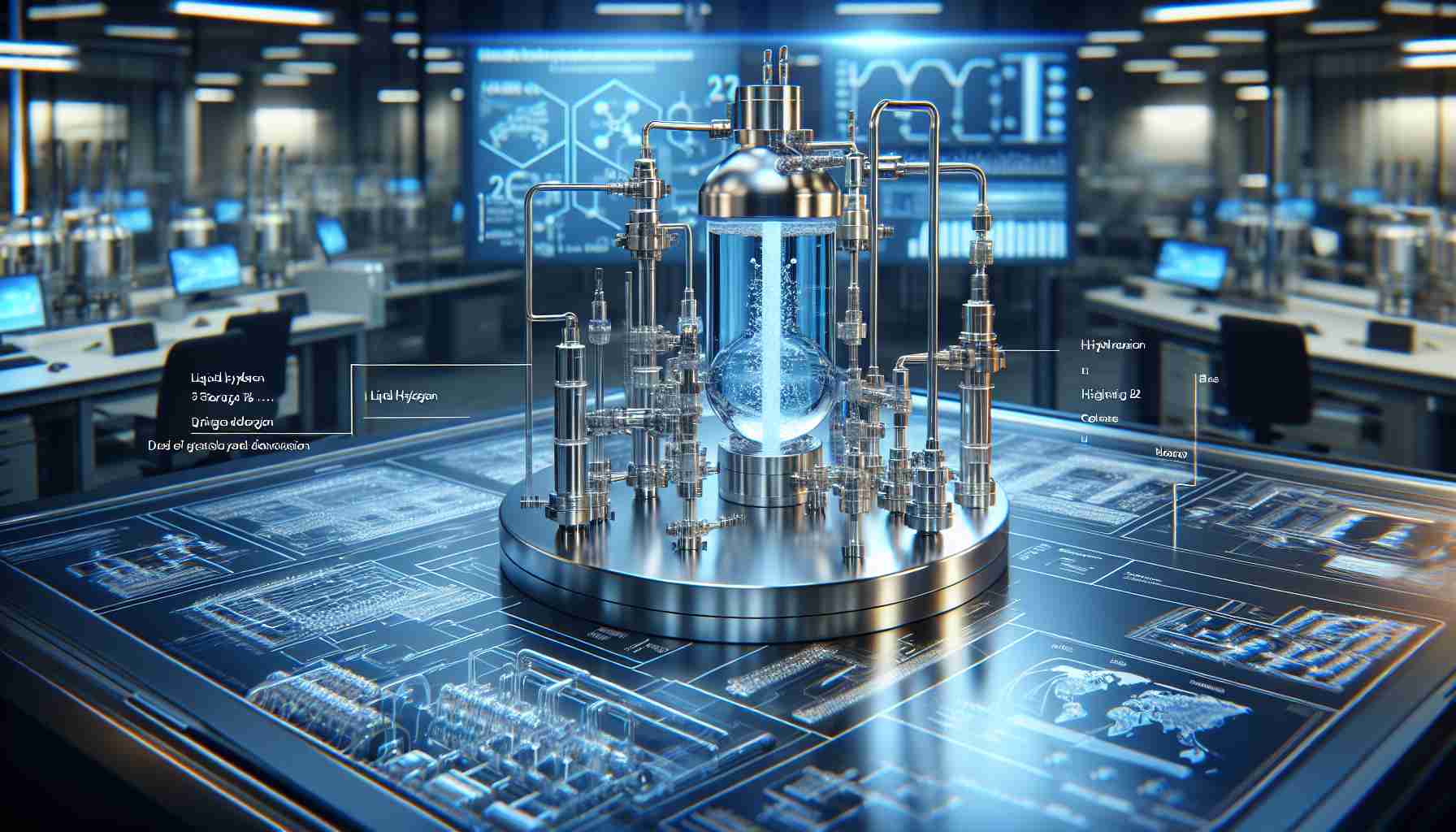

The newly developed vacuum insulation system is tailored to address critical challenges in the hydrogen industry, particularly focusing on the effective storage and transportation of liquefied hydrogen at a chilling temperature of -253°C. With this advanced technology, the large tanks resemble that of thermos flasks, an achievable feat previously untested on such a large scale in maritime applications.

Notably, while NASA’s largest LH2 tank has a capacity of 5,000 m³, maritime applications require tanks that can hold over four times that volume. HD KSOE’s revolutionary design offers an efficient solution by significantly reducing the time taken to achieve vacuum conditions in larger tanks.

Industry collaborations with prominent entities like Woodside Energy and Mitsui OSK Lines aided in the design and validation process. The collective efforts have led to groundbreaking results, garnering support from international classification societies. This innovative development is seen as a significant leap towards achieving sustainable solutions and decarbonization in the maritime sector.

Hydrogen Revolution on the High Seas: Transforming Maritime Energy Storage

Lloyd’s Register (LR) has granted an Approval in Principle (AiP) to HD Korea Shipbuilding & Offshore Engineering Co., Ltd. (HD KSOE) for an innovative vacuum-insulated liquid hydrogen (LH2) tank system. This recognition comes after successful testing of a large-scale vacuum chamber, marking a significant milestone in maritime hydrogen technology.

Key Features of the Innovative LH2 Tank System

The newly developed vacuum insulation system is tailored to address critical challenges in the hydrogen industry, particularly focusing on effective storage and transportation of liquefied hydrogen at a chilling temperature of -253°C. With this advanced technology, the large tanks resemble that of thermos flasks, an achievable feat previously untested on such a large scale in maritime applications.

Specifications and Performance

– Temperature: Capable of sustaining -253°C for optimal hydrogen storage.

– Capacity: Designed to exceed NASA’s largest LH2 tank capacity of 5,000 m³, meeting maritime needs efficiently.

– Vacuum Pressure: The design significantly reduces the time taken to attain vacuum conditions compared to traditional methods.

Use Cases and Advantages

The advancement in LH2 tank technology opens various use cases in the maritime industry, including:

– Decarbonization Efforts: Supports global initiatives aiming to reduce carbon emissions from shipping.

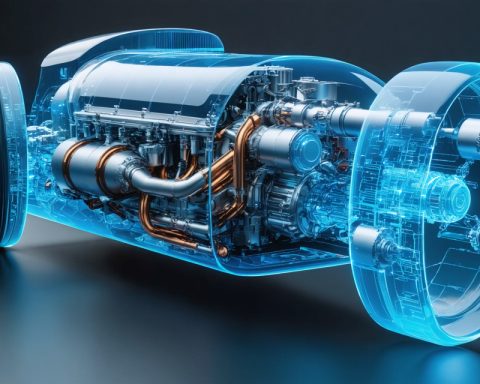

– Hydrogen as a Fuel Source: Enables the use of liquid hydrogen as a cleaner alternative to conventional marine fuels.

– Research and Development: Provides a platform for further exploration in hydrogen-based propulsion systems.

Industry Collaborations

Notably, industry collaborations with prominent entities like Woodside Energy and Mitsui OSK Lines have been instrumental in the design and validation process. This cooperative approach has facilitated the development of a technology that gains support from international classification societies and has the potential to meet regulatory challenges effectively.

Pros and Cons of Maritime Hydrogen Storage

Pros

– Sustainability: Contributes to reducing the overall carbon footprint of the maritime industry.

– Efficiency: Improved tank technology enhances the speed of loading and transporting hydrogen.

– Innovation: Represents a breakthrough in engineering that may influence other industries.

Cons

– Cost: Initial investment in technology may be high, potentially leading to increased shipping costs.

– Infrastructure: Requires significant changes in current maritime fueling infrastructure to accommodate new tank systems.

– Safety Concerns: Handling and storing hydrogen at extreme temperatures presents safety challenges that must be thoroughly managed.

Pricing Insights

While exact pricing details for the new LH2 tank systems are currently unavailable, ongoing developments in hydrogen technology and increasing demand for cleaner fuels suggest potential cost reductions through economies of scale and advancements in technology.

Conclusion and Future Trends

The introduction of HD KSOE’s vacuum-insulated liquid hydrogen tanks represents a crucial step toward sustainable maritime operations. As the industry moves towards decarbonization and reduced reliance on fossil fuels, innovations like these will play a pivotal role. The continuing collaboration between technology developers and maritime operators will be crucial in overcoming challenges and successfully implementing hydrogen solutions in shipping.

For more insights on maritime innovations, visit Lloyd’s Register.